Project Schedule Risk: Why “Monitoring and Control” Isn’t the Same as Delivery

When the Schedule Is “Managed” but Still Sinking

When the Schedule Is “Managed” but Still Sinking

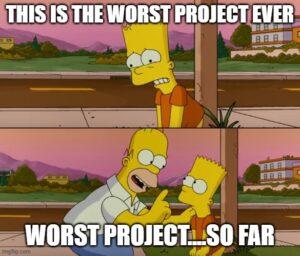

Not everything can be turned into a process—especially in product development, where discovery and uncertainty are unavoidable. But there is a dangerous gap between acknowledging uncertainty and pretending it is under control. The image illustrates a familiar scenario: a project manager confidently “monitoring and controlling” while the actual project schedule quietly sinks beneath the surface. This is project schedule risk in its most recognizable form—visible, predictable, and frequently ignored.

Understanding Project Schedule Risk

Project schedules are plans, not guarantees. They are based on assumptions about scope stability, resource availability, technical maturity, and execution speed. Project schedule risk arises when assumptions change while the schedule remains unchanged. A colleague of ours once said, a project without slack is on a death march. That is absolutely true. Slack is our friend; there must be space for tasks and objectives to move without impacting the final delivery date.

Project slack (also called float) is the amount of time a project activity can be delayed without delaying either its dependent activities or the overall project completion date.

Monitoring dates without addressing underlying causes creates the illusion of control while risk accumulates underwater. Ideally, we have metrics for tasks and objectives to enable predictive measures (lead indicators). Whether we approach our project using conventional project management or an agile approach, there will be task dependencies. Failing to acknowledge or mitigate these dependencies is a path to project failure.

Project Schedule Risk in Product Development

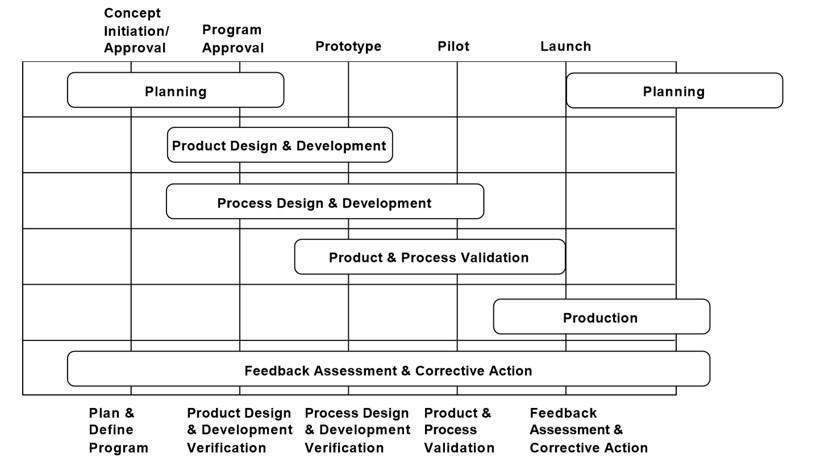

In product development, schedules are often created before the work is fully understood. Early optimism, incomplete requirements, and evolving designs all contribute to uncertainty. There may be technical uncertainties and customer-required learning. A rigid schedule, when we lack a solid understanding of the technology or techniques required for success, is a failure to recognize that we do not know everything that needs to be known for that success. Agile approaches help, but we must still acknowledge this unknown. Product development is not a manufacturing line; we should not treat it like that.

Common Development Drivers of Schedule Risk

In practice, recurring failure themes emerge in product development. Development takes what it takes in the schedule. For example, we have seen organizations undertake work while managers questioned whether the volume could be effectively absorbed. In our haste to promptly meet the customer’s demands, and enable income generation for the organization.

- Overemphasis on meeting the customer needs to the exclusion of what is required to do so.

-

Immature requirements

-

Unvalidated designs

-

Late discovery of technical complexity

-

Testing competing with launch dates

When learning is treated as a disruption rather than progress, project schedule risk builds silently until milestones are missed. We can choose to recognize that product development requires learning, or we can have that reality imposed on us by a schedule failure. If you have done extensive product development work, you will know that a significant source of risk lies in engineering and product testing. These are often shortchanged.

When learning is treated as a disruption rather than progress, project schedule risk builds silently until milestones are missed. We can choose to recognize that product development requires learning, or we can have that reality imposed on us by a schedule failure. If you have done extensive product development work, you will know that a significant source of risk lies in engineering and product testing. These are often shortchanged.

Manufacturing Absorbs Schedule Risk

When development delays propagate downstream, manufacturing becomes the shock absorber. Ideally, we have closely connected the manufacturing development effort with the product development effort. If you are developing products for the automotive industry, you know there is a close connection between product development and the manufacturing line development (APQP). Still, we cannot make decisions about the manufacturing line until we have information about the product design. These two domains go hand in hand to get the product out the door effectively. If the product’s introduction date does not change, the manufacturing line will not be capable of producing the product at the required volume, cost, and expected quality.

Manufacturing Symptoms of Project Schedule Risk

-

Compressed ramp-up timelines

-

Incomplete work instructions

-

Processes finalized too late

-

Rework normalized as “launch behavior.”

At this stage, project schedule risk translates directly into cost overruns, quality issues, and operational stress. Manufacturing teams must recover time lost upstream.

Monitoring vs. Managing the Schedule

Monitoring a schedule means tracking dates as they move. Managing a schedule means changing decisions. This includes associating metrics with the progress of any given task on the schedule. We do not mean an arbitrary gut feeling for the progress. We are referring to a method of measuring progress.

What Real Schedule Management Requires

-

Surfacing risks early—even when uncomfortable

-

Trading scope, not just time

-

Replanning when assumptions change

-

Aligning testing, readiness, and launch decisions

Without these actions, “monitor and control” becomes a reporting exercise rather than a risk management function.

Reducing Project Schedule Risk Across the Lifecycle

Effective organizations treat schedules as dynamic risk models, not fixed commitments.

Effective organizations treat schedules as dynamic risk models, not fixed commitments.

In Product Development

-

Link milestones to evidence, not optimism

-

Treat unknowns as schedule risks, not background noise

-

Adjust plans as learning occurs

In Manufacturing

-

Require readiness criteria before ramp-up

-

Escalate schedule compression as operational risk

-

Feed launch issues back into development planning

Reducing project schedule risk requires coordination, not heroics.

If the Schedule Is Underwater, Monitoring Won’t Save It

The imag e is humorous because it is accurate. Schedules do not fail suddenly—they sink gradually while reports remain calm. Project schedule risk is not caused solely by poor tracking but also by delayed decisions. Even when we have metrics and we are continuously monitoring, beyond the “intuition”, I think we are 30% complete. This applies especially to the schedule. Our team members bring self-preservation and optimism, but not a clear objective review of what is true and valid. Conflict is beneficial when managed well, and the project manager or project lead is responsible for understanding this and having the appropriate skills to do so.

e is humorous because it is accurate. Schedules do not fail suddenly—they sink gradually while reports remain calm. Project schedule risk is not caused solely by poor tracking but also by delayed decisions. Even when we have metrics and we are continuously monitoring, beyond the “intuition”, I think we are 30% complete. This applies especially to the schedule. Our team members bring self-preservation and optimism, but not a clear objective review of what is true and valid. Conflict is beneficial when managed well, and the project manager or project lead is responsible for understanding this and having the appropriate skills to do so.

Until organizations shift from watching schedules to actively managing risk, the schedule will continue to drown—quietly, predictably, and repeatedly.

For more information, contact us:

The Value Transformation LLC store.

Follow us on social media at:

Amazon Author Central https://www.amazon.com/-/e/B002A56N5E

Follow us on LinkedIn: https://www.linkedin.com/in/jonmquigley/

https://www.linkedin.com/company/value-transformation-llc

Follow us on Google Scholar: https://scholar.google.com/citations?user=dAApL1kAAAAJ