Asking for More Late in the Project

Asking for more…

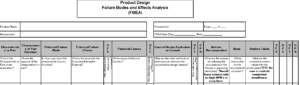

Recently, I overheard a project manager discussing the use of a quality tool for their project. The project is well underway. Can you guess the tool under discussion? It was the DFMEA or Design Failure Mode Effects Analysis. There are a couple of things wrong with starting the discussion at this point, but let’s start with the FMEA itself.

Project and FMEA

The DFMEA (also has a cousin for manufacturing processes called the PFMEA) are a couple of the tools from the APQP (Advanced Product Quality Planning) suite. The FMEA provides a structured review or critique of the proposed product design or in the event of the of the PFMEA the manufacturing processes. I will not go into details on the structure of the FMEA, if you are interested give us a call. We can coach your team. It is sufficient to know that this is a well structured and planned activity. We draw upon our historical record, and our team members experience and theorize what can fail and how. We will then develop some verification actions to test the veracity of our assumptions or perhaps just out right alter the design or process as a result of this critique / review.

Late does not work in the project

First, an effective DFMEA is integrated with the product development work – early. We explore the potential failures of our burgeoning design. We think of the potential failures that can happen, as well as the cause. We devise ways to test to see if our theorized failure mode is correct. We generate situations to which the product will be subjected that will confirm our refute (verification activities) the failure modes we believe will happen. The result of this verification work are recorded. We will then review the implications of the tests results on our product design incarnation. Specifically, what shall we do with the design? For example, we may modify demonstrated weak areas, or we may accept the design in present form. Waiting late in the project will put tooling money at risk. Additionally, we waste time with product iterations that will likely require rework or forbid start over. So we need project time to reap the benefits – start early.

Second, the DFMEA is a cross functional approach and requires key talent and sufficient time to both go through the critique. We may have people research past failures for similar products. We will need talent and time to review the design intent and conduct the cross functionally, set up the verification plan and subsequent actions. We will need a variety of talent and we will need time spent focused on these activities.

Conclusion

Asking for the time or money late in the project for something such as an FMEA is not productive. What happens if you find something significant? Is there sufficient business case to perform the development work twice? Additionally, this is not likely to inspire sponsor confidence in the end product. The only good that can come from performing this work late, and it is a real benefit, is to know what sort of product quality issues you are getting ready to launch on your customer. It my be better than nothing, but the best solution is to consider these quality activities – time and cost early on in the project and stick with it.